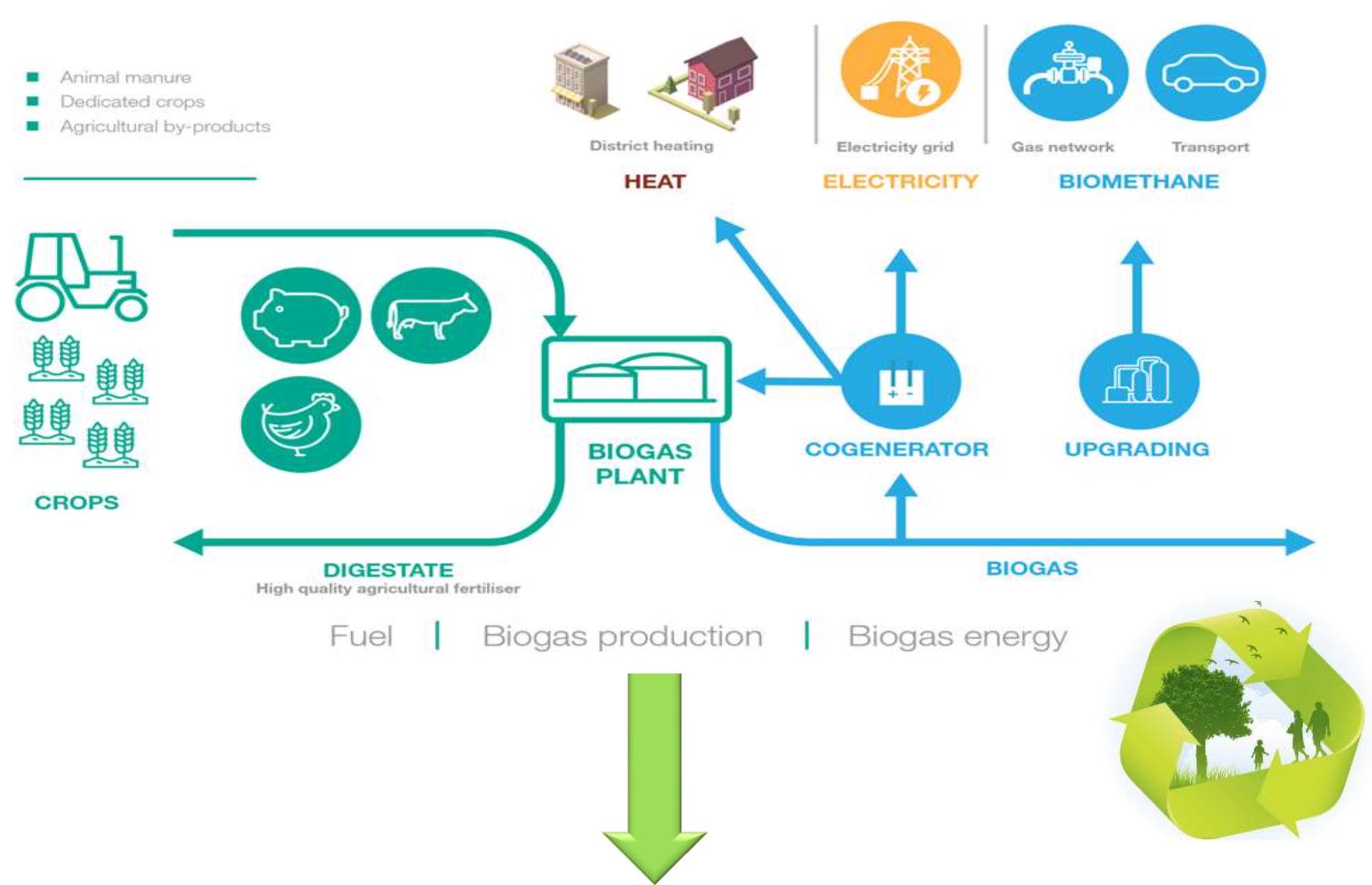

Description of the Biomethane Plant

2. Matrix treatment area - The pre-treatment of the matrices takes place via a completely sealed Pasco loading hopper which processes the organic matrices and conveys them to the biodigesters.

3. Bio digesters for anaerobic treatment - The biomethane plant through an anaerobic digestion process, inside Bio digesters in the absence of oxygen, recovers the biogas from the matrices used which is subsequently treated in the Upgrading system. Anaerobic digestion means the degradation of organic substance by microorganisms in anaerobic conditions that separate the biogas containing the methane molecule CH4 from the digestate.

4. The biogas upgrading system uses membranes to separate the CH4 biomethane, which is then sent to the liquefaction system for transport to the truck fleets.

The membranes retain CO2, hydrogen sulfide, carbon monoxide, nitrogen and ammonia. The recovered CO2 can be used in medicine, food or agriculture.

5. The composting plant transforms the digestate from anaerobic digestion into a compostable soil improver for agriculture, which can be used directly on the fields or after aerobic treatment in Bio tunnels or Bio Cells.

The composting process lasts at least 90 days and the final product serves as agricultural fertilizer.